Supply Chain Risk Management: How to Strengthen Your Operation

Last Updated: August 19, 2025

The internet, expanding transportation, and globalization have created a highly interconnected supply chain. Your food and clothes are produced in various countries, hopping from place to place until they end up at a local store. While products are more accessible than ever, this interconnectedness also means more risks.

Disruptions can be anything from surprise weather to malicious cyberattacks. With so many new exposure variables, businesses need to think beyond basic logistics. They need proactive, strategic plans to manage risks. Supply chain risk management (SCRM) helps your organization predict risks and maintain operations for better long-term performance. A risk-based approach lets companies build stronger, more competitive supply chains in an increasingly unpredictable world.

Table of Contents

- What Is SCRM?

- Types of Supply Chain Risks

- Why Traditional SCRM Falls Short and How Risk-Based Approaches Can Help

- What Is a Risk-Based Approach?

- What Should Your Supply Chain Risk Management Framework Look Like?

- Known vs. Unknown Risks

- How Technology Can Improve SCRM

- Best Practices for Building Supply Chain Resilience

- How LogicManager Supports Smarter SCRM

- SCRM Frequently Asked Questions

- 1. What Are the Four Types of Risk in Supply Chain Management?

- 2. What Are the Top Supply Chain Risks?

- 3. What Are the SCRM Reliability Standards?

- 4. How Does SCRM Relate to ERM?

- 5. What Is the Difference Between SCRM Software and Supply Chain Management Software?

- 6. How Do You Evaluate Risk Management Tools?

- Take Control of Your Supply Chain Risks With LogicManager’s Solutions

What Is SCRM?

Supply chain risk management is identifying, assessing, handling, and monitoring hazards that can impact your supply chain. Disruptions might impact raw material sourcing, transportation, cybersecurity, and any other part of the supply chain risk management process. The goal is to create a plan to minimize risks affecting your business.

An effective SCRM program considers internal and external risks. If you aren’t prepared, operational inefficiencies can slow an operation down as much as geopolitical shifts. Since supply chains are made of multiple tiers of suppliers, partners, and systems, disruptions anywhere along the chain can have a ripple effect on production and delivery. Instead of waiting to correct after these disruptions, SCRM helps businesses understand their vulnerabilities and plan to avoid slowdowns proactively.

Types of Supply Chain Risks

A strong supply chain starts with research and understanding. When a business understands its exposure points, it can manage them. Whether that’s sudden tariffs on materials or supplier delays, dozens of factors influence when and how products reach consumers.

Here are some of the major categories of potential delays. Use these supply chain risk examples to find the vulnerabilities that can impact your operation:

1. Natural and Global Events

Extreme weather events, pandemics, and geopolitical conflict all have significant ripple effects. They often happen with little warning and lead to long-lasting production, logistics, and sourcing delays. For example, when the Ever Given container ship blocked the Suez Canal in 2021, it delayed $9.6 billion worth of goods per day. It took six days to clear the canal, impacted shipping schedules globally, and caused disruptions in the shipping industry.

Trade wars, sanctions, pandemics, and major disasters have similar effects on the supply chain. Companies caught in these events must be able to source from unaffected areas to maintain production. If goods become too expensive due to tariffs or sourcing issues, your company needs an alternative strategy built on global supply chain risk management.

2. Supplier Risks

Even if you build up your logistical defenses against issues, there are other vulnerability points. Weak links in the supply chain can shut everything down. Hazards like supplier bankruptcy, capacity shortfalls, delivery delays, and quality control failures are all possible. If you depend on only one supplier for critical components, any problems on their end mean cascading failures.

Operational vulnerabilities also pop up around outdated or poor infrastructure. If you lack real-time visibility into inventory, how can you manage performance during disruptions? If you lack accuracy when tracking raw materials, how will you know what you’re running out of? Your business needs to have updated technologies and varied suppliers to reduce the chances of risks halting an operation.

3. Cybersecurity and Technology Gaps

Digital tools are a central part of today’s world. While they make exchanging and managing information easier, they also introduce new risks. If you rely on cloud systems and connected devices, you need strong protection against attackers.

Cyberattacks can stop production, corrupt data, and expose sensitive information. In 2024, the global average cost of a data breach was $4.9 million, up 10% from the previous year. When threat actors send phishing emails or malware, and team members access them, it can cost your company. Just a single point in a system can ripple out, leading to financial and reputational loss.

Even unmalicious issues like cloud service outages or Internet of Things (IoT) failures can disrupt logistics. When your systems go down, you need to be ready to act. Related problems, like a semiconductor shortage, can limit production or prevent you from accessing the tools you need to keep up with the competition.

4. Reputational Risks

Global warming is a concern for consumers and governments everywhere. Modern supply chains face scrutiny for their impact on the environment and human rights. When surveyed, 60% of people said they’d pay more for sustainable product packaging. Failing to vet suppliers for environmental and social compliance can lead to reputational damage or regulatory concerns.

Even if your company strives to stay green and protect workers at different facilities, sourcing raw materials from areas with more relaxed standards can affect consumers. They might not purchase from you due to these concerns. Additionally, companies face pressure to limit their emissions and reduce waste. Overlooking environmental regulations can put your business at risk.

5. Demand Volatility

Consumer behavior now shifts with the latest online trends, economic concerns, and technology. Many supply chains that operate on just-in-time (JIT) models can struggle to keep up with these rapid changes. For example, the early COVID-19 pandemic saw shortages of essential items like toilet paper and canned goods. Companies that lacked an inventory buffer struggled to keep up with demand.

An effective SCRM strategy considers demand fluctuations with predictive analytics, strategic stock levels, and flexible scaling.

Why Traditional SCRM Falls Short and How Risk-Based Approaches Can Help

Traditional SCRM is often reactive and disconnected from different company areas. These methods look at isolated pain points instead of considering how they affect the entire operation. Addressing delays, inventory bottlenecks, or single supplier issues after they occur leaves you on your back foot. They’re temporary solutions that fail to protect you for the next time something happens.

Two common limitations of traditional SCRM are a lack of cross-coordination and poor real-time visibility. Risk management often sees minimal integration across departments. Your IT, compliance, and finance teams might have blind spots or redundant measures since they never coordinate. Limited real-time visibility also prevents teams from monitoring vulnerabilities as they change. With a siloed, digitized supply chain, your operation might have slower response times and more damage. Everyone must work together to be proactive to succeed.

What Is a Risk-Based Approach?

A risk-based approach to SCRM is proactive instead of reactive. You start by identifying critical risks across your supply chain. Then, businesses anticipate likely issues caused by these hazards. You’ll assess how likely they are and what the impact will be, and then develop controls for limiting them. A centralized enterprise risk management (ERM) platform can make this process easier, creating a coordinated, easy-to-navigate space for your SCRM.

What Should Your Supply Chain Risk Management Framework Look Like?

A successful SCRM program is built to be structured, repeatable, and data-focused. No matter your industry or company size, you can use a strong SCRM framework to reduce vulnerability exposure and keep your business running. Use this framework as a foundation for your company and create a strategy that prepares you for major risks:

1. Identify

The first step in building an effective SCRM strategy is identifying potential supply chain disruptions. Go beyond direct relationships and consider how events across the entire ecosystem could cause delays. Consider:

- First-tier suppliers

- Third-party dependencies

- Manufacturing sites

- Transportation routes

- Geographic areas with regular large-scale events

- Critical service providers

Risks can also be internal, like reliance on a single vendor, or external, like severe weather patterns near a supplier. You need visibility into these risks to mitigate them. Use resources like an ERM platform with prebuilt risk libraries to find common hazards across the industry, supply chain tiers, and regulations. Teams can use these libraries to ensure they explore all risk categories.

Map vulnerabilities across departments and assets to avoid silos. You want an interconnected map that provides a complete picture of vulnerabilities.

2. Assess

Once you’ve identified the risks, it’s time to assess their potential impact and chances of happening. A supply chain risk assessment is based on preferences, but your operation can use expert support, risk scoring models, heat maps, and simulations to assess your main risks. You can also look for platforms that provide scoring tools. These supply chain risk analysis solutions let you define scoring thresholds and criteria, and then assign a score to each supply risk.

Understanding the biggest risks lets you know where to focus your efforts. While preparing for lower-likelihood disruptions can be challenging, teams can focus on the highest-chance and highest-impact areas to maximize risk handling effectiveness.

3. Mitigate

Next, businesses must integrate strategies to reduce vulnerability exposure and improve resilience. It’s not enough to know what to expect — companies need to minimize the damage a risk can do to productivity. Common mitigation measures include:

- Supplier diversification: Having multiple suppliers avoids any one becoming a single point of failure.

- Nearshoring: Relocating operations to a closer location shortens supply routes and reduces exposure to global events.

- Inventory buffers: Keeping inventory buffers prevents stockouts during surprise demand fluctuations.

- Updated technology: Invest in supply chain risk management technology that improves transparency and automates processes to boost efficiency and risk management.

Mitigation goes beyond operational fixes, too. Your business should update policies, training programs, and vendor onboarding to ensure everyone understands hazard handling efforts. If a vendor is too relaxed about security, data could be breached. Everyone needs to be on the same page when it comes to preventing risks.

4. Monitor

Risks are constantly changing, which means vulnerability management is continuous. After you’ve established mitigation efforts, you need to monitor them. Ongoing SCRM monitoring tells you how teams are managing ongoing risks and keeps you updated on new threats. Watch for risks by:

- Tracking key performance indicators (KPIs) related to inventory turnover and supply chain movement.

- Reviewing vendor performance metrics like delivery times and defect rates.

- Auditing supplier compliance with contracts and regulatory guidelines.

- Watching weather and geopolitical alerts for relevant regions.

Organizations should also schedule regular assessments to ensure consistent monitoring. Use annual risk audits or quarterly supplier reviews. Standardized monitoring combined with real-time data will keep you updated on the entire supply chain.

5. Report

Reporting is the final step in an SCRM framework. Even the best risk management plan can fail if communication is poor. Risk reporting keeps board members involved and ensures stakeholders understand the current landscape. Use detailed mitigation documentation and high-level summaries to report on mitigation activities, timelines, and responsible parties.

Reporting creates clear trails so you can track risks, department efforts, and audits. Keeping everyone in the loop ensures nothing slips through the cracks. Additionally, reporting improves your business’s transparency. Teams can see how their efforts are making a difference, and you protect the company from concerns over risk handling. Vulnerability responsibility should be shared by everyone at your company, not just the supply chain team.

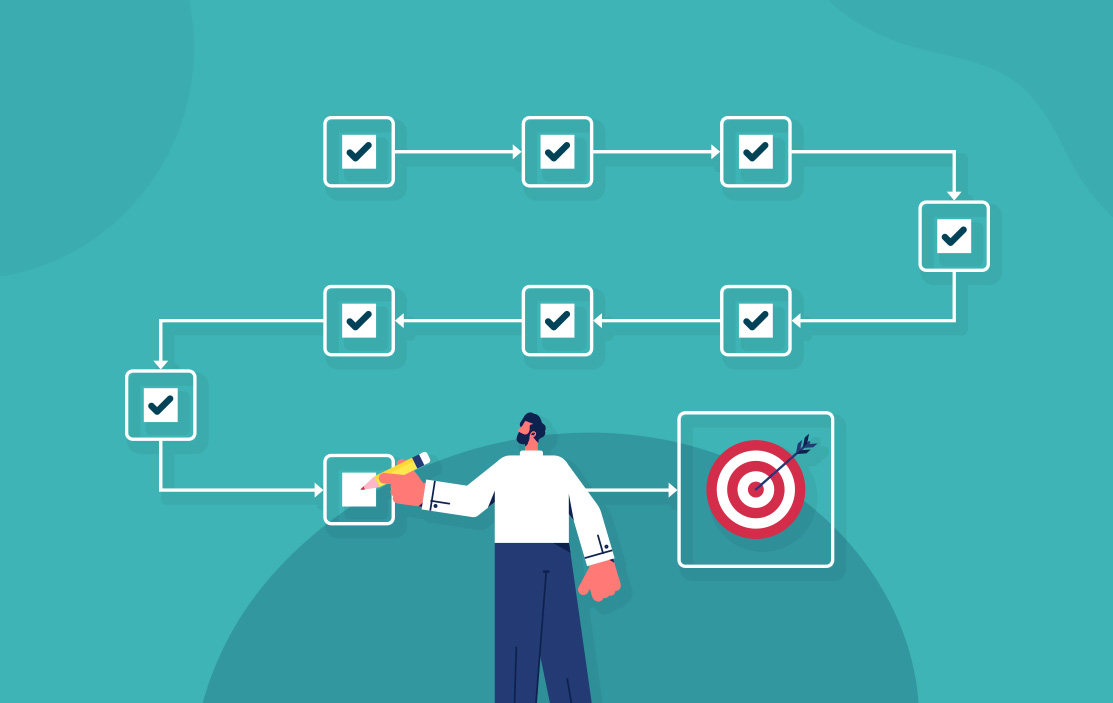

Known vs. Unknown Risks

Even with a solid framework, you still need to know how to navigate supply chain risks. Some are predictable, while others will happen without warning. Building a truly resilient operation means being prepared to manage known and unknown hazards.

What Are Known Risks?

Known risks are concerns businesses can identify in advance and evaluate using data, past trends, or expert support. These risks are recurring or based on predictable conditions. A supplier operating on narrow margins may be a financial exposure point, while a factory in a hurricane-prone area can be flagged for natural disaster exposure.

Other known risks might be:

- Supplier bankruptcy.

- Past record of quality issues.

- Delays due to seasonal demand spikes.

- Documented noncompliance with regulatory standards.

These risks are measurable and visible within your supply chain or vendor pool. Risk assessment in supply chain management involves scoring and classification models to rank these hazards. Analyze known exposure points using data and take action through sourcing alternatives or inventory buffers.

Prepare for known risks by:

- Using scoring models to prioritize threats.

- Maintaining updated risk registers.

- Implementing, tracking, and updating risk mitigation plans.

What Are Unknown Risks?

Unknown risks are difficult or impossible to predict. These events happen when rare disruptions, sudden threats, or hidden ripples occur. Something like a global pandemic does not follow familiar patterns. It’s impossible to predict when these events will happen or how long they’ll impact your supply chain. Because unknown hazards don’t follow familiar patterns, they are more challenging to detect and quantify for risk assessment measures.

Unknown disruptions include:

- Sudden shifts in regulatory policies around material exports.

- Unexpected global conflicts in a key country.

- Tsunamis or other weather events in a critical supplier area.

- An unknown or zero-day vulnerability exploited by a cyber attacker.

While unknown risks are unpredictable, businesses can still prepare for their effects. The goal is to develop better responsiveness, agility, and resilience so your team sees less damage when disruptions happen. You can’t predict every scenario, but you can bounce back faster each time.

Prepare for unknown risks by:

- Using simulation exercises to test reactions to unexpected events.

- Building strong defenses through compliance audits and supplier vetting.

- Creating contingency plans with supply alternatives and emergency logistics.

- Using analytics to map risk ripples across departments and processes.

How Technology Can Improve SCRM

Global competition means supply chains move faster and operate leaner. You may be competing with businesses on the other side of the world while delivering to customers in a completely different region from your home base. Organizations can deploy advanced technology to stay ahead of the competition. Modern SCRM uses technology to detect and respond to vulnerabilities in real time.

Look to artificial intelligence (AI), real-time data, automation, and cloud computing to upgrade your risk management in supply chain handling and stay on the cutting edge of supply chain protection.

1. Artificial Intelligence and Machine Learning

AI and machine learning (ML) are the latest technologies changing the game. They are integral to predictive modeling, helping businesses anticipate risks before they hit. These tools analyze vast amounts of data. They look at weather patterns, market trends, historical data, supplier performance, and political information to find patterns and predict future vulnerabilities.

ML algorithms can detect anomalies in vendor delivery patterns. Based on the risks they see, they’ll recommend alternative shipping routes or sourcing strategies. That way, the organization can pivot proactively, saving time and money. When integrated with ERM platforms, ML and AI give you insights tailored to your business and based on real-time data.

2. Real-Time Tracking and IoT

The IoT describes a network of sensors and technology that all connect and share data. Modern shipping containers, fleets, and warehouse equipment can all have devices that transmit data to digital monitoring systems. The result is constant real-time data on everything from location and movement to temperature, humidity, and pressure.

These real-time tracking capabilities give companies insight into product status at every stage. Sensors alert teams to temperature issues with sensitive goods, while managers can see stockouts before they happen. The IoT also makes delay or recall traceability easier. Teams can quickly document, track, and mitigate exposure as soon as the IoT alerts them to concerns, making response times faster and more proactive.

3. Automation

Automation is another tool that improves supply chain resiliency. Your business can reduce human error and improve speed with robotics and automated tools. With automated rote work, your operation can move through production faster, with fewer mistakes in hazardous areas. Look for these automated technologies to boost productivity:

- Automated platforms: Assess vendor risk scores and flag anomalies without manual review.

- Robotic process automation (RPA): Sort, label, and move goods in warehouses.

- Automated workflows: Analyze data automatically and escalate to human team members if the system detects new risk factors.

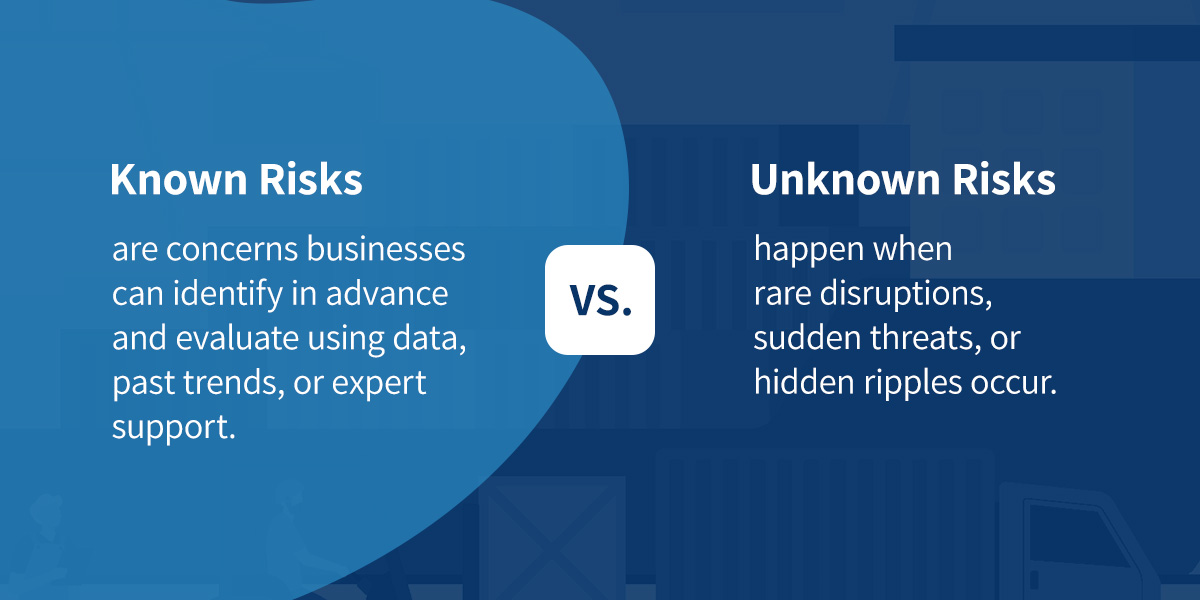

4. Cloud Computing

Cloud-based infrastructure is another way to streamline your SCRM process. Relying on local servers involves investing in your own on-site data storage, processing power, and team members to monitor and fix issues. Cloud computing lets you share data, expand storage and collaborate without overextending business infrastructure. Off-site data storage and cloud services maintain collaboration with stakeholders, no matter their location.

Use cloud services to view dashboards, update risk assessments, and view supplier statuses from any device — even when you’re on the road. Cloud platforms are also scalable. Companies can easily expand their SCRM program as supply chains grow. Plus, cloud-based infrastructure handles updates and security patches centrally. Everyone gets updated together, avoiding outdated software and unprotected endpoints.

5. Blockchain Technology

Blockchain is a transparent, unchangeable ledger used to track transactions and assets. It can support better traceability and anticounterfeiting efforts. When integrated, each transaction or goods movement is recorded in the blockchain. It’s a permanent record of who handled what, where, and when. Blockchain has the potential to help the supply chain become more trustworthy.

However, blockchain technology is currently difficult to scale and requires high energy consumption. As a newer technology, it has a more limited worker pool and has not been widely adopted. In the future, a more energy-efficient blockchain ledger could help manage hazards.

Best Practices for Building Supply Chain Resilience

Every business faces a disruption at some point. Our supply chains are too interconnected to remain unaffected by all risks. Building a resilient supply chain means anticipating challenges and minimizing vulnerabilities. When you can prepare effectively and respond quickly, you protect the company from the worst effects of a disruption. Use these SCRM best practices to strengthen your supply chain in an ever-changing world:

1. Diversify Suppliers

Relying on a single supplier or a small vendor pool for critical materials and services is risky. If something delays their work, you risk a complete shutdown at the first sign of disruption. Diversification spreads your sourcing across multiple vendors and areas to mitigate this vulnerability.

Have alternate suppliers identified and ready to go in case of disruptions. Look for vendors in different regions with unique logistical paths. If you select vendors across the world but they all collide at a specific transport point, that’s still a major risk waiting to happen. Track suppliers, routes, and risk factors from a centralized system and ensure you’re diversified enough to reduce disruptions like weather and surprise regulations.

2. Use Nearshoring and Regional Redundancy

Globalization and outsourcing have allowed companies to bring down costs. Sourcing from cheaper labor or material regions maximizes profits but puts you at greater logistical risk. The further away all your suppliers are, the more global liabilities you take on. When extreme weather, political issues, and shipping delays slow overseas supply, you could face weeks of downtime.

Mix some nearshore or regional redundancy options to limit risk impacts. You want to be able to source from groups closer to your primary markets if risks pop up around the world. Nearshoring shortens lead times and keeps you from being too dependent on high-risk areas. For example, investing in sourcing in Mexico or the Midwest for U.S. businesses may raise some production costs, but it avoids financial hits from overseas bottlenecks.

3. Maintain Inventory Buffers

JIT inventory allows companies to reduce warehousing costs, but this leaner operation style also exposes them to more hazards. With sudden demand surprises and global disruptions, JIT stocking leaves you with no wiggle room. Building inventory buffers for the most critical products keeps you from dealing with stockouts during lean times.

A tailored safety stock bridges the gap during disruptions. Even if your suppliers are delayed, you still have inventory to sell. You’ll make a profit as you start up alternate sourcing or logistics plans. A quality ERM platform will let you align inventory strategies with supply chain risk profiles. The result is precise safety stocking based on real-world data.

4. Improve Vendor Monitoring

Supplier risk is one of the main considerations when evaluating supply chain liabilities. Your operation needs complete insight into third-party performance and compliance to ensure there are no hidden surprises. Make sure to analyze:

- Labor and environmental practices.

- Vendor credit health and financials.

- Fourth-party dependencies.

- Cybersecurity controls and data handling.

It’s common to deep-dive into vendors during onboarding. Once you’ve approved a vendor, it’s easy to relax your oversight and become complacent. But suppliers can change over time, exposing you to new risks. Ongoing monitoring is critical for protecting a supply chain. Use regular reviews, audits, and performance tracking to ensure vendors are staying on top of quality and security.

5. Model Worst-Case Scenarios

Some hazards will hit out of nowhere. Your best approach is to prepare for the most likely and most damaging scenarios so you’re ready to respond to the worst disruptions without issue. Modeling is a great way to train your business response and see the impact of specific risks. Use business impact analyses, tabletop exercises, and simulation tools to rehearse responses regularly.

Scenario modeling shows companies the gaps in their communication, resource use, and protocols. Proactive testing helps you fine-tune mitigation plans, making them faster and more effective. Additionally, teams will clear up confusion before the actual event, creating a more effective response plan.

6. Implement Regular Risk Assessments

Risks are always changing. Political instability in one area may increase suddenly, while other areas could see changes in weather patterns that affect logistics. Jurisdictions might change their regulatory requirements, affecting markets. With so many variables changing, you need to prioritize regular exposure assessments in your supply chain risk management strategies.

Internal or external factors can influence a supplier’s risk rating. Regular assessments should evaluate:

- Exposure to environmental, cyber, or political risks.

- A supplier’s importance to your business.

- Shifts in compliance or output performance.

- Changes in financial health or working conditions.

7. Invest in Risk Management Platforms

Centralizing your SCRM plan with Software-as-a-Service (SaaS) platforms can improve consistency and scalability. Managing vendor data and risk scores from separate systems leads to data silos and redundancies, while a centralized system brings everything together in one place.

Use a SaaS-based tool that offers real-time dashboards, helpful insights, workflow automation, and cross-functional collaboration. You’ll easily juggle complex data while cutting right to the information you need. These platforms can also integrate with third-party tools so you can maintain your operational efficiency. Risk management platforms help you stay ahead of new risks so your business can keep up with the competition.

How LogicManager Supports Smarter SCRM

Even the best strategy needs supporting supply chain risk management tools. Juggling spreadsheets, vendor reviews, weather data, and all the other critical information is an enormous amount of work for your company. A platform built for ERM can help you stay connected and on top of the latest concerns. That’s where LogicManager comes in.

LogicManager’s ERM platform provides the foundation a business needs to design, execute, and scale a smarter SCRM program. Our solution aligns your supply chain oversight with areas like IT hazards, regulatory compliance, and cybersecurity. With everything in one centralized place, you get faster risk management and fewer silos.

LogicManager’s range of features makes supporting and scaling your supply chain risk management solutions easier. We offer:

- Prebuilt risk libraries: Our prebuilt risk libraries, controls, and assessment templates let you start building a risk program immediately. These configurable libraries allow companies to tailor their setup to vendors, regions, and compliance requirements.

- No-code implementation: We offer drag-and-drop tools for easier liability assessment building. Create workflows, dashboards, and reports for your business’s needs without a developer. This flexibility empowers departments to contribute without relying only on IT teams.

- Expert support: We pair every customer with a dedicated advisory analyst. These vulnerability experts help configure workflows, interpret risk data, and provide tailored support. We want to help your risk capabilities grow effectively within the company.

- Seamless integration: LogicManager integrates with over 50 third-party systems, including BitSight, RiskRecon, DocuSign, Workday, and Office 365. You get up and running faster and achieve better collaboration across your systems.

Risk Ripple Analytics

What truly sets our services apart is Risk Ripple Analytics. This proprietary tool lets organizations visualize how a single disruption can ripple through interconnected sectors. A supplier outage or contract breach can suddenly become an inventory shortage, risking productivity. A compliance issue might impact legal departments, delay production, and damage customer relationships.

By mapping dependencies, LogicManager enables teams to assess the full scope and impact of every risk. With detailed Risk Ripple Analytics, you can build more responsive, specific mitigation strategies. Our solution gives you a full view of your vulnerabilities and how they could affect operational success.

SCRM Frequently Asked Questions

Whether you’re building an SCRM framework from the ground up or refining your existing plan, knowing the basics of supply chain hazards is essential. Here are some answers to common questions to help you better evaluate your risks and mitigation efforts.

1. What Are the Four Types of Risk in Supply Chain Management?

The four main types of risks in supply chain management are political, economic, environmental, and ethical. Most risks fall into one or more of these categories. Your business and its suppliers, vendors, and partners are all affected by one of these risks at some point. Global SCRM strategies consider these categories and rank the biggest concerns to reduce their impact when they happen.

2. What Are the Top Supply Chain Risks?

Risks are constantly changing, and different groups will evaluate them differently. Some of the top supply chain risks in 2025 are:

- Climate change

- Geopolitical instability

- Rising cybercrime

- Mineral scarcity

- Forced labor concerns

3. What Are the SCRM Reliability Standards?

The SCRM Reliability Standards are guidelines to help high and medium impact bulk electric system (BES) Cyber Systems address risks. They lay out security objectives for these businesses so they can mitigate vulnerabilities. While they apply to BES Cyber Systems, noncyber companies can use them to refine their SCRM approach.

4. How Does SCRM Relate to ERM?

Enterprise risk management is a framework for managing concerns across an entire business. SCRM focuses on your supply chain specifically, such as supplier relationships and logistics. ERM platforms connect your SCRM data to other areas like IT, finance, and compliance. This way, you get the whole risk picture and see how every area impacts the others.

5. What Is the Difference Between SCRM Software and Supply Chain Management Software?

Supply chain risk management software streamlines managing and reducing supply chain risks, particularly third-party, operational, cybersecurity, and compliance liabilities. Supply chain management (SCM) software is built for overseeing logistics, procurement, transportation, and inventory. Risk management in SCM is critical for protecting business operations.

6. How Do You Evaluate Risk Management Tools?

Finding the right ERM platform for your SCRM strategy is critical. Look for:

- Customizable risk assessment templates

- Third-party integrations

- Centralized dashboards and risk registers

- Cross-functional collaboration

- Scenario modeling tools

- Workflow automation

- Expert support for troubleshooting and strategy

Take Control of Your Supply Chain Risks With LogicManager’s Solutions

Your SCRM program needs to be proactive and reactive. Businesses must stay on top of real-time data, changing risks, and world events to keep their supply chains moving. LogicManager empowers organizations to connect supply chain oversight with enterprise-wide risk management. Our unified, risk-based approach lets all operations find and mitigate risks for better business continuity.

You get full visibility across all departments with LogicManager’s Risk Ripple Analytics, ERM solution, and expert advisory services. From day-one onboarding to outcome-driven licensing and fixed pricing, we simplify scaling your SCRM program without added complexity. Let us help you build a more efficient, effective supply chain. Get started with your free demo today.